Bringing An End To Single Use Plastic

Poseidon is a high-tech speciality chemical recycling company focused on developing, commercialising and delivering technology to recycle PET plastic waste. Our aim is to significantly reduce the volume of PET waste worldwide, and ultimately bring an end to single-use PET plastics.

The Poseidon Process

Our proprietary waste-to-polyester technology breaks down all forms of waste PET plastic, including textiles, carpets, films and bottles into Poseidon rBHET™; a low-cost, sustainable feedstock for the global PET industry.

Sustainable Recycled Feedstock

rBHET™ is used to remanufacture high-grade PET for food grade plastic packaging, bottles and containers, thereby creating a circular economy. Our process is also currently being used by our partners in the sportswear industry to develop the world’s first fully circular sportswear range.

Technology Benefits

Our technology means that PET should no longer be considered a single use plastic. All PET is now a valuable and fully recyclable feedstock. Poseidon’s low processing costs will enable a rapid scale-up of the amount of recycled PET in circulation, thereby significantly reducing the volume of PET lost to landfill or incineration.

Proven Technology

Our proven enhanced recycling technology (or ‘the Poseidon Process’) has been producing high-grade rBHET™ at our Teesside pilot facility since January 2020.

Independent corporate partners have verified its quality through the manufacturing of polyester with recycled content between 25 – 100%.

Our technology is selective for PET and therefore and provides a solution for problematic waste streams including black microwave trays, mixed plastics and textiles which can be unsuited to mechanical recycling and persistent in the environment.

PET Applications

Food Packaging

PET is one of the most widely used plastics for carry-home meals which can be warmed in the oven or microwave.

Carpets

Polyester (PET) fibre is an increasingly popular choice for carpet due to its lustrous appearance, high level of stain resistance, eco-friendly properties and low cost.

PET Bottles

PET bottles are widely used for packaging sodas, water, juices, salad dressings, cooking oil, peanut butter, shampoo, liquid hand soap, mouthwash and pharmaceuticals.

PET Film

PET is widely used as the lidding film for trays and punnets of fresh produce as well as a barrier film in packets for produce with extended shelf life. Other applications include electrical components, healthcare, print, photovoltaics and flexible electronics.

Automotive PET

PET has numerous uses in the automotive industry due to its strength and featherlight properties. It can be utilised for wiper arms, gear housing, engine covers and connector housings.

Textiles

Recycled PET is an eco-friendly alternative that has flame-retardant, water repellent and breathable properties. Applications include sportswear, shoes, clothing, umbrellas, and rainwear. Polyester is the go-to fabric for sportswear due to its light weight, elasticity and excellent 'wickability'. Its unrivalled durability and water-resistance make it a choice fabric for outdoor gear. Its insulating properties make it ideal for fleece clothing as well as the filler in pillows and comforters.

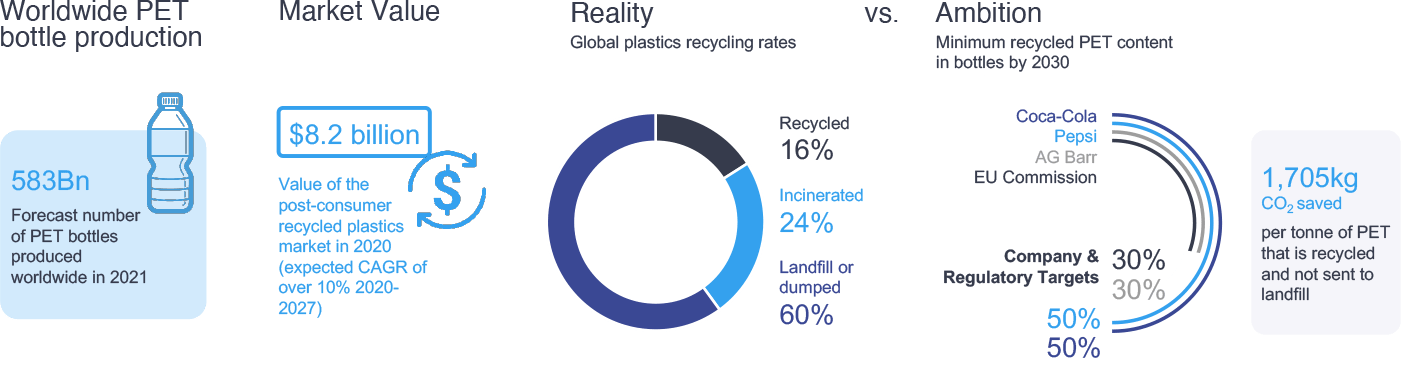

Multi-Billion Dollar Market

Plastic waste is one of the most significant global environmental problems facing us today. We possess an economical and scalable solution that can recycle all types of polyester waste back to a high-grade material and prevent it from entering the environment.

The global polyester market was valued at $110 bn in 2019.

As countries around the world put legislative measures in place to force manufacturers to come up with solutions, the need for our technology and its value proposition will both increase dramatically.